Paxxal Industries is revolutionizing the material handling industry. We are an industrial manufacturer, delivering pallets worldwide that are higher in value and lower in cost than any comparable product in the global market.

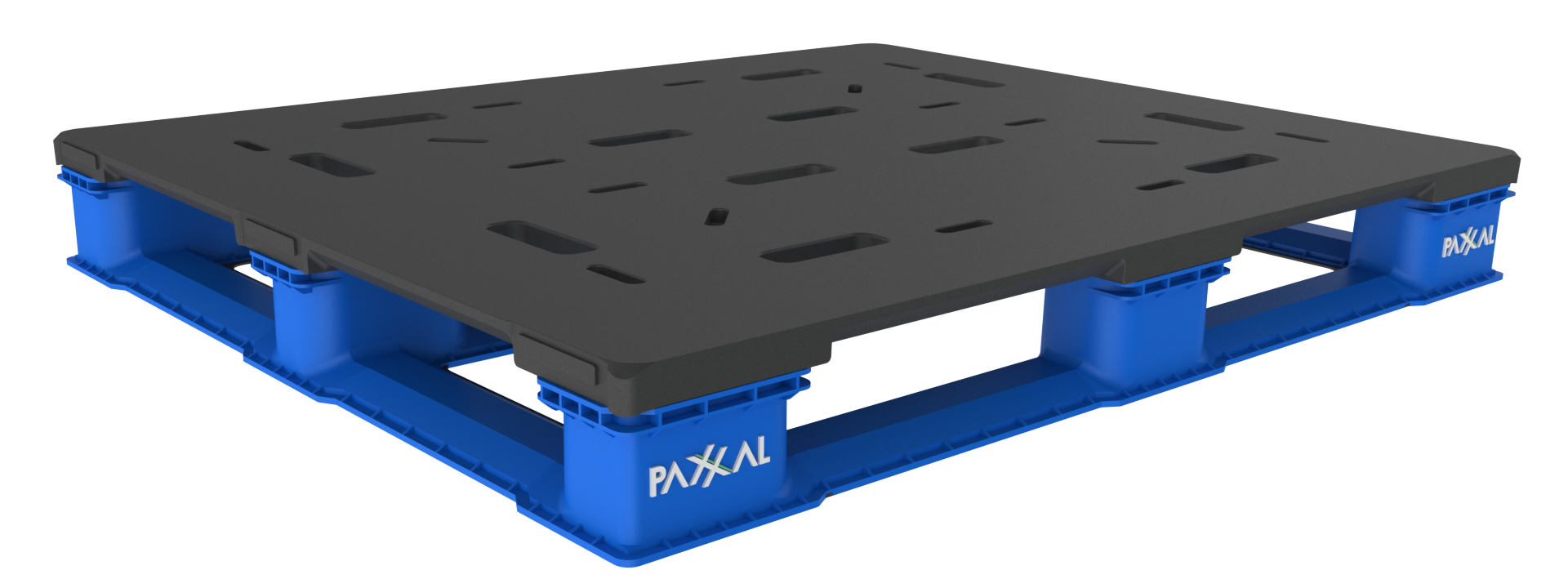

Paxxal’s unique and patented formulations provide a pallet portfolio that is 100% recyclable and more cost-effective than other pallets available in the market today. This material, combined with our unique molding process creates a pallet with a solid core that is stronger and more impact resistant than other plastic pallets.

Our customized, fully automated rotational mold processes ensure precision-made, value-adding pallets with the ability to generate high volume orders efficiently.

Higher capacity, lower cost, unmatched product.

Over a decade of research has gone into our revolutionary rotomolding processes, material, and machinery, surpassing all other conventional molding methods. The REVO machine and its technology is an exciting breakthrough in polymer molding and manufacturing. Able to produce dramatically more parts per cycle with a smaller footprint and lower material cost than any current molding processes used in the market, our rotomolding guarantees a rapid investment return as well as a consistent, quality, precision-made product.

We have dedicated over a decade of research and development toward our formulation, processes, and fully-automated equipment in order to perfect our manufacturing process and ensure that we deliver consistent, uncompromised quality.

We provide customers with long term solutions that are hygienic and recyclable.

With a life expectancy of over 7 years, Paxxal’s pallets provide a high return on investment. Our pallets are not infallible however, and we understand that breakage and damage can occur, resulting from careless forklift driving, improper storing of goods and products as well as a host of other reasons.

Click to download the North American Paxxal Pallet Spec Sheet.

*Samples available please contact our sales team for pre-release information

Size |

48in x 40in x 5.62in |

Weight |

< 50lbs |

Top Deck Coverage |

80% + Textured |

Pallet Entry |

4- Way |

Edge Racking Load Capacity |

2,800+ lbs |

Dynamic Load Capacity |

5,000+ lbs |

Static Load Capacity |

30,000+ lbs |

Temperature Range |

-30F to 140F |

Certifications |

UL Pending |

Material |

High Density Polyethylene + Solid Proprietary Core |

Options |

Color / Branding / Tracking Technology |

Size |

120cm x 100cm x 16cm | +/- 48in x 40in x 6.30in |

Weight |

+/- 60lbs |

Top Deck |

3mm Perimeter Lip + Drainage Channels |

Pallet Entry |

4-Way |

Edge Racking Load Capacity |

2,200+ lbs |

Dynamic Load Capacity |

5,500+ lbs |

Static Load Capacity |

22,000lbs |

Temperature Range |

-40 to 150F |

Material |

High Density Polyethylene + Solid Proprietary Core |

Options |

Color / Branding / Tracking Technology |

Enter your email address to be immediately sent:

Pack Expo 2022 Booth 6738

Reusable Packaging Association Announces 2022 Excellence in Reusable Packaging Award Winners Award Ceremony to Take Place Oct. 25 at 3pm at PACK EXPO International Booth 6737 WASHINGTON, DC (September 13, 2022) – – The Reusable Packaging Association (RPA) has announced the winners of the prestigious 2022 Excellence in Reusable Packaging Awards. This year’s awards feature […]

Read More